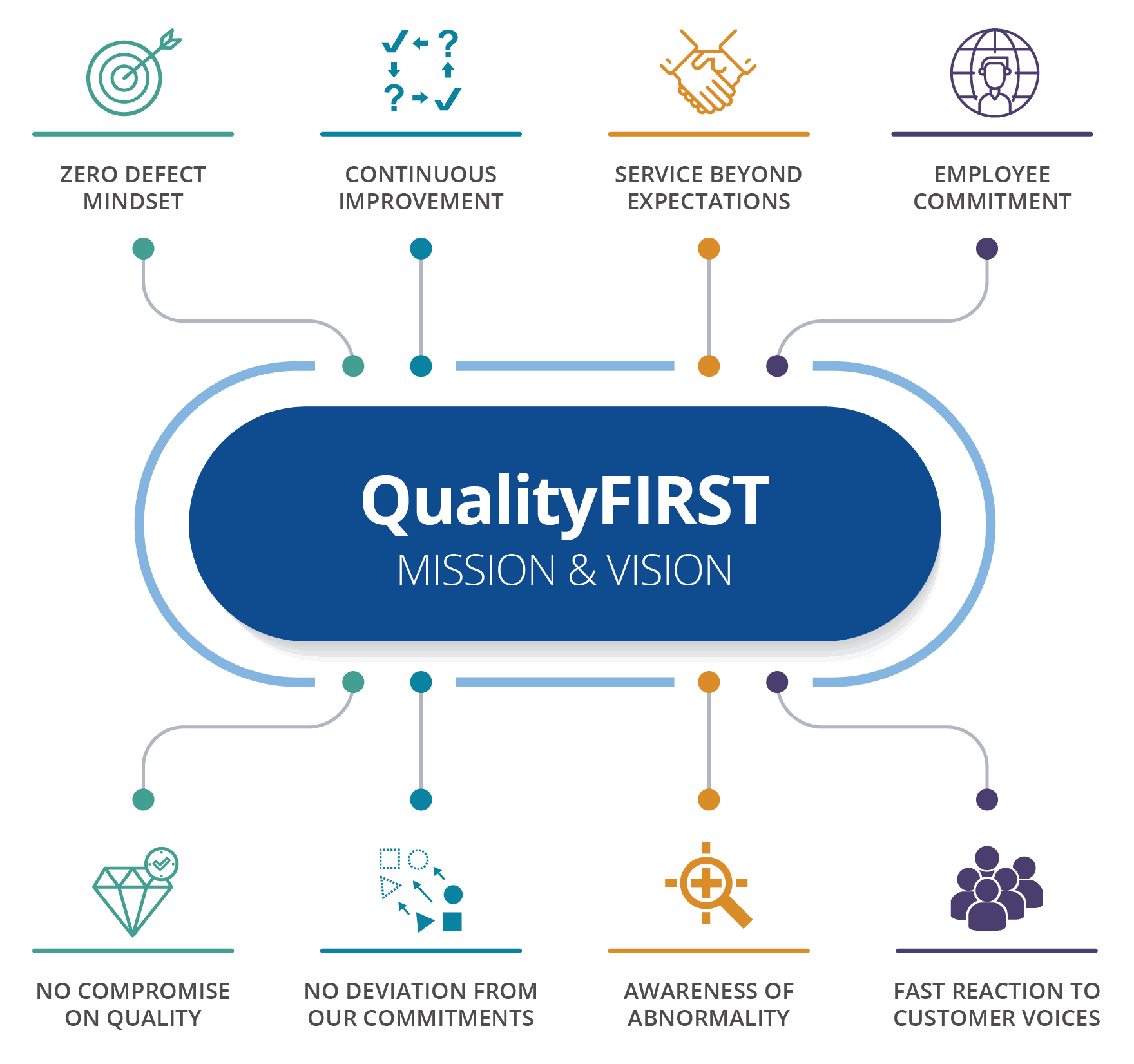

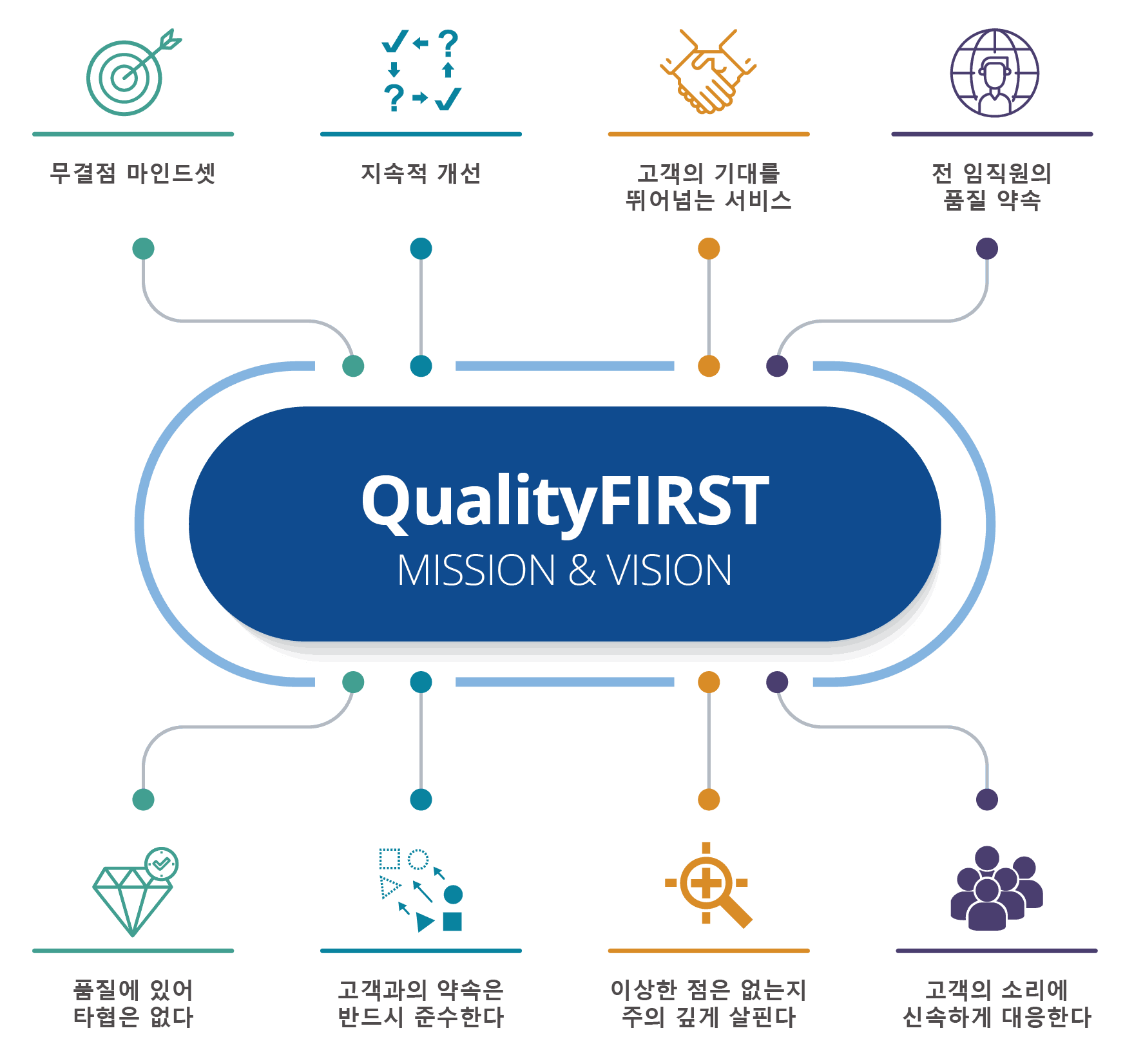

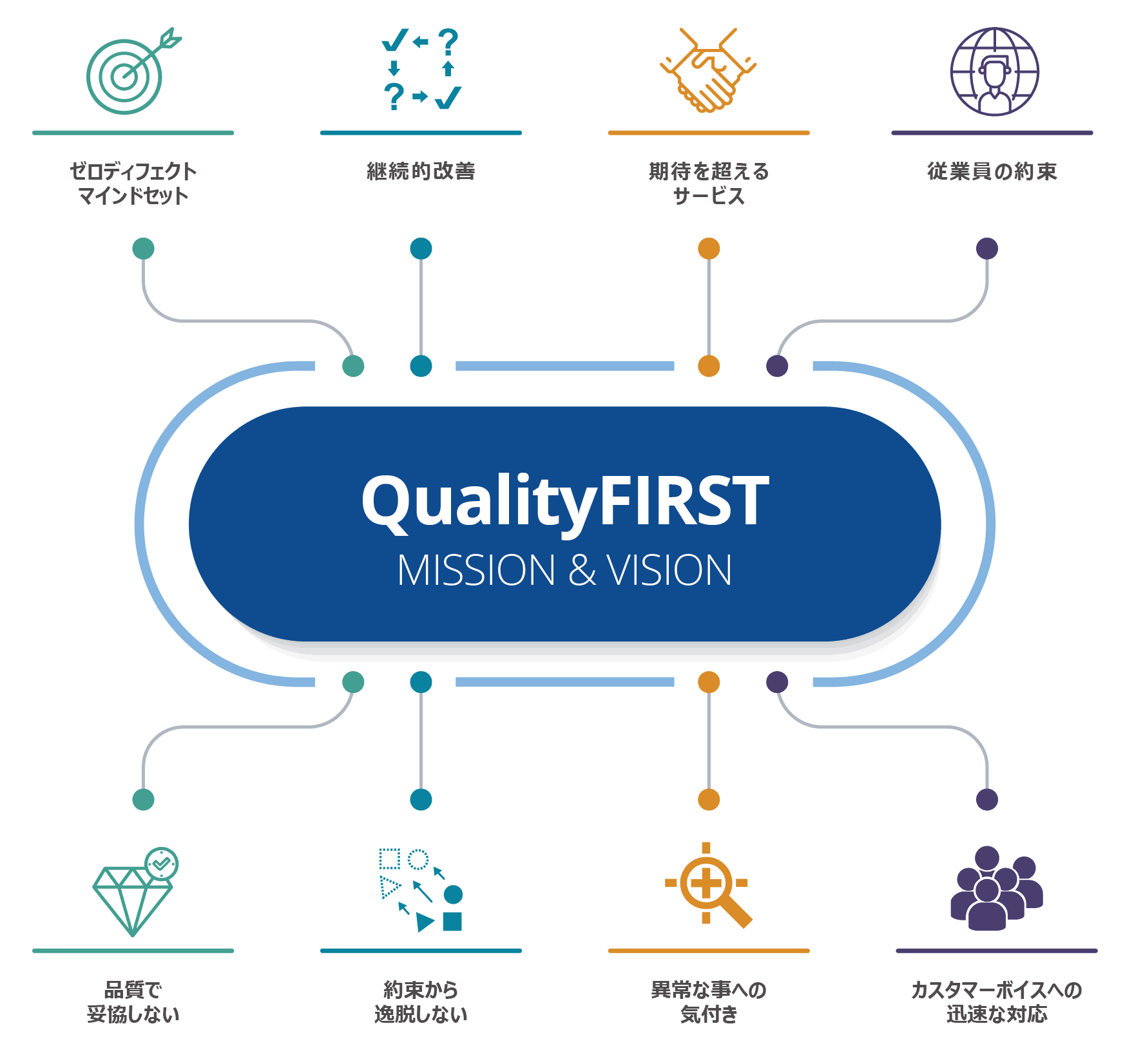

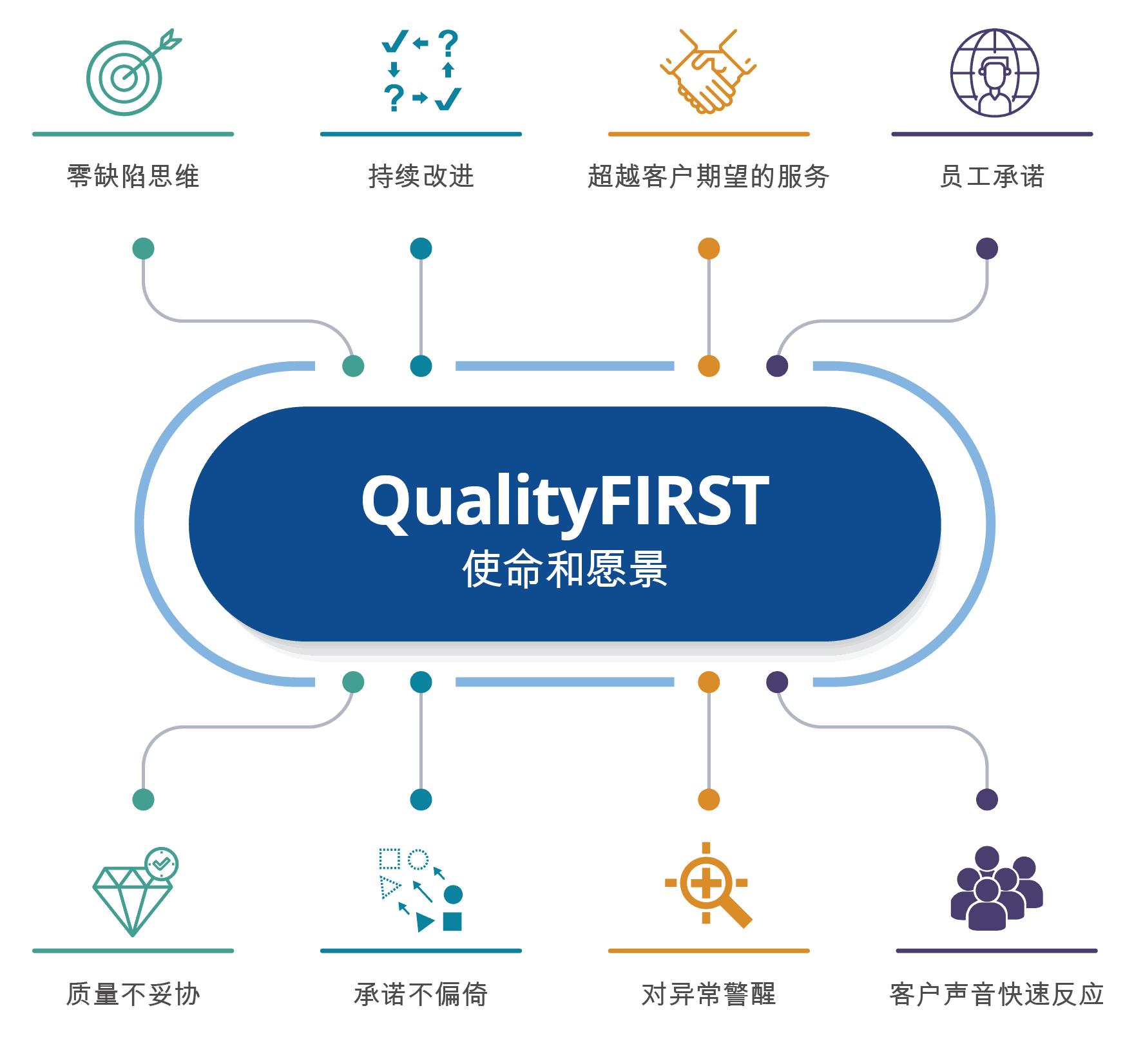

Our commitment to customer satisfaction is conveyed through QualityFIRST

Amkor delivers industry-leading quality services to customers through our QualityFIRST initiative.

Amkor recognizes the need to extend the quest for quality beyond manufacturing. QualityFIRST is embedded in our processes ensuring the same quality standards for all Amkor employees.

Amkor embraces the principles and concepts of QualityFIRST and incorporates them in all segments of our business from new product development to manufacturing, administration, sales and customer service.

Automotive Quality

Amkor is the world’s top automotive OSAT with the highest quality

Automotive quality expectations now measure defects in the “number of quality incidents” instead of PPM or PPB. As the world’s largest OSAT for automotive ICs, we continuously strive to exceed customer requirements on a path toward zero defects.

Automotive Quality Systems

- Zero defect mindset

- Amkor QualityFIRST culture

- Automotive Golden Rules

- Automotive quality standard

- IATF-16949

- AIAG Core Tools & VDA 6.3

- Customer-specific automotive requirements

- Change management

- Product-based FMEA/control plan

Automotive Process Controls

- Automotive standard process and control

- Factory automation

- Unit Level Traceability (ULT)

- Hands-free operation

- Designated resources

- 5S, foreign material control

Supplier Quality

Our valued suppliers are key to achieving Amkor’s QualityFIRST in the semiconductor assembly and testing industry

Amkor’s global Supplier Quality Management (SQM) teams drive our suppliers to proactively work towards Amkor’s quality expectations. Our suppliers are encouraged to make systematic and ongoing improvements to their products and processes through rigorous monitoring of material conformance to meet Amkor’s requirements.

- Supplier system requirements

- Procurement (PO) specs per material type

- Incoming inspection

- IQA specs per material type (various IQA specs)

- Raw material control – supplier CAR

- Raw material MRB

- Supplier quality system assessment

- Quality system audit

- Manufacturing process audit

- Raw material/supplier qualification

- Supplier audit (Amkor internal)

- Supplier rate & ranking

Continuous Improvement

We learn from everything we do and every day we strive for perfection

Amkor has designed continuous improvement activities across worldwide factories to achieve a steady, ongoing improvement to products, processes and services through constant review, measurement and action by Plan-Do-Check-Act (PDCA) cycle.

- Customer Task Force Team (CTFTs)

- Zero defect management TFTs

- 5S and FM (chlorine) TFTs

- Best Known Method (BKM) fan-out systems

- Process Improvement Council (PIC)

- Corporate Equipment Engineering (CEE)

- Customer audit & internal audit

Factory Certifications

Amkor adheres to internationally recognized certification standards for Quality Management, Environment, Health & Safety Management, and Information Security Management. Amkor’s commitment to these standards ensures that our operations meet the highest levels of quality, safety, and security.

Questions?

Contact an Amkor expert by clicking the request info button below.