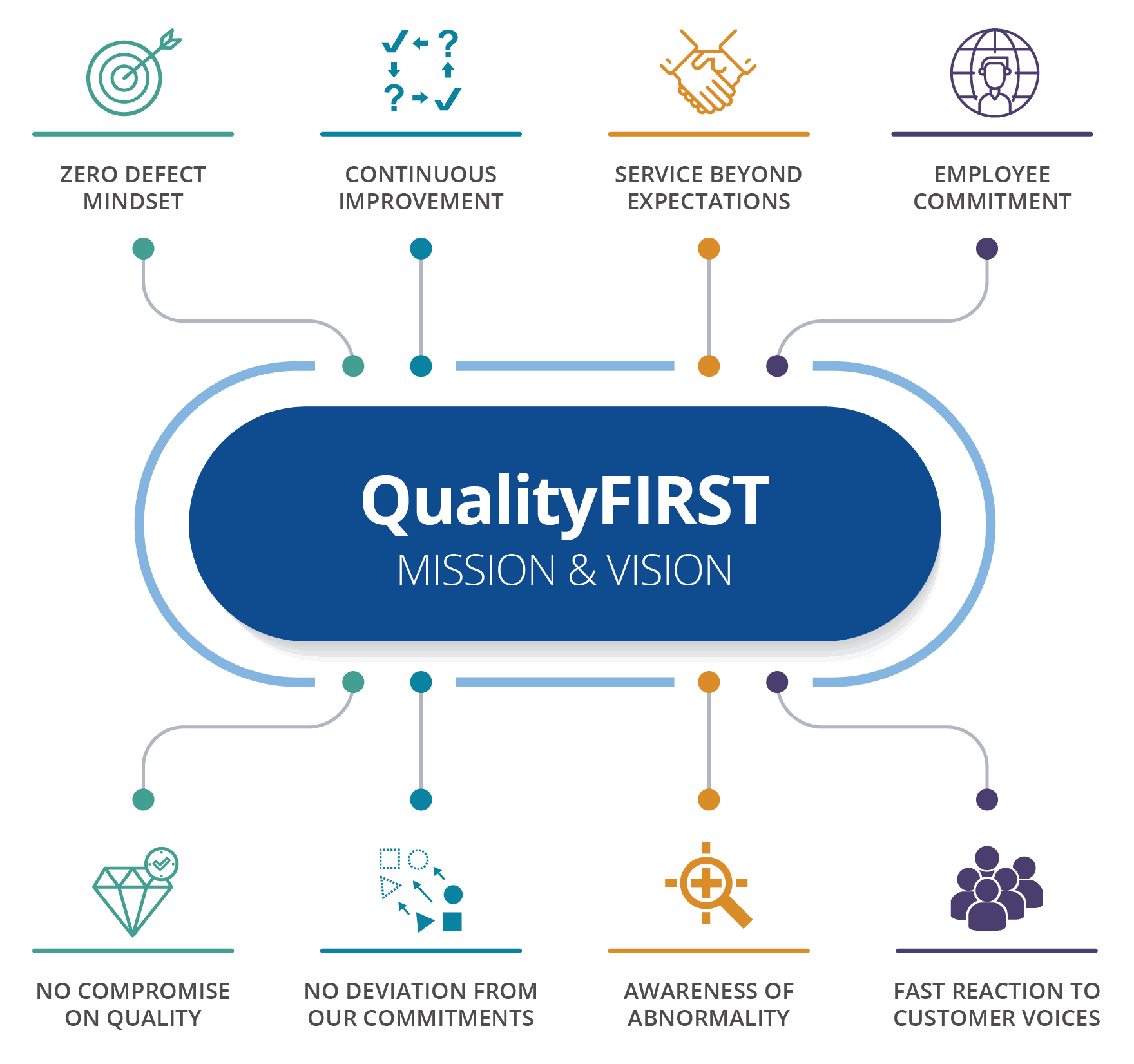

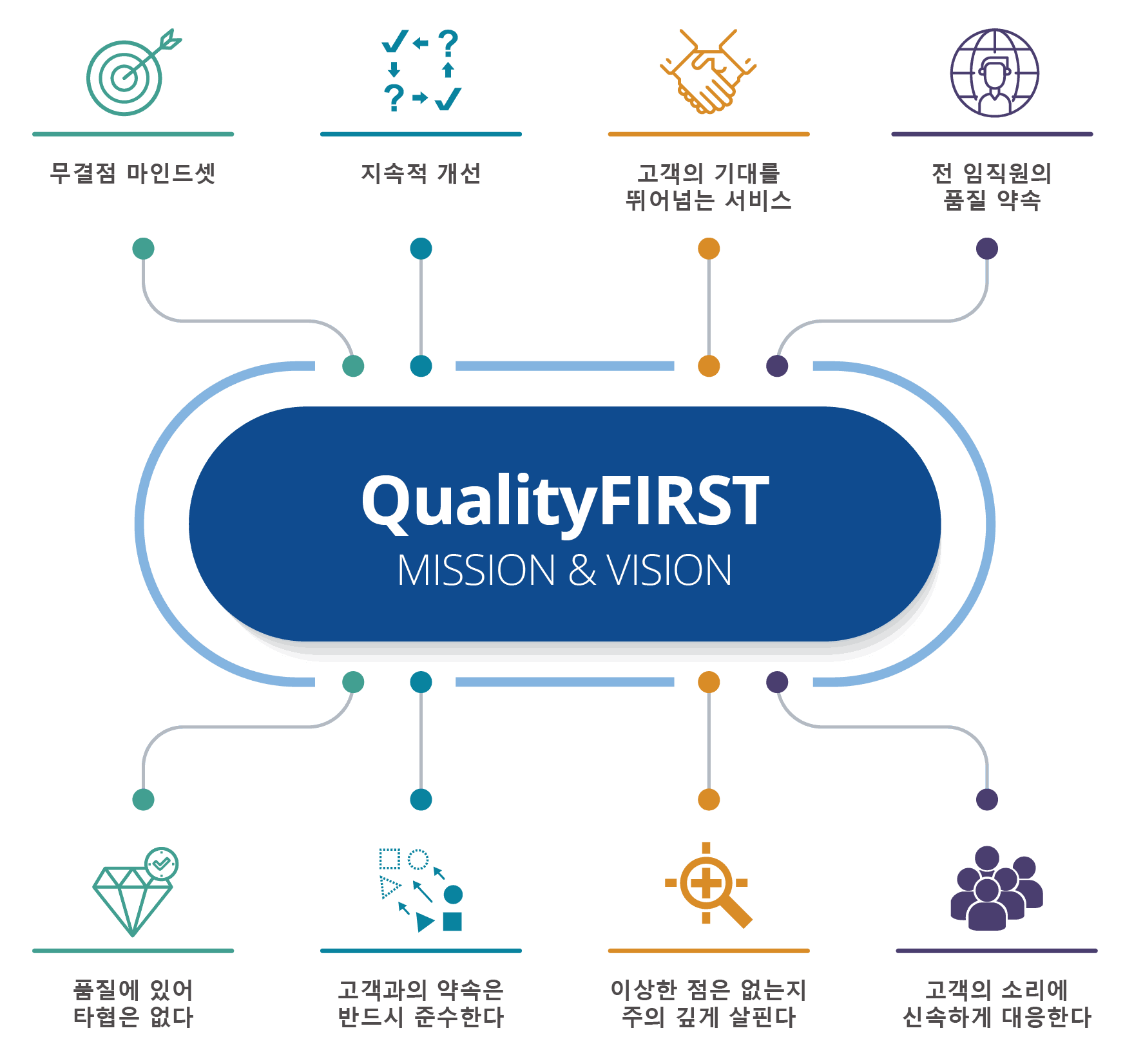

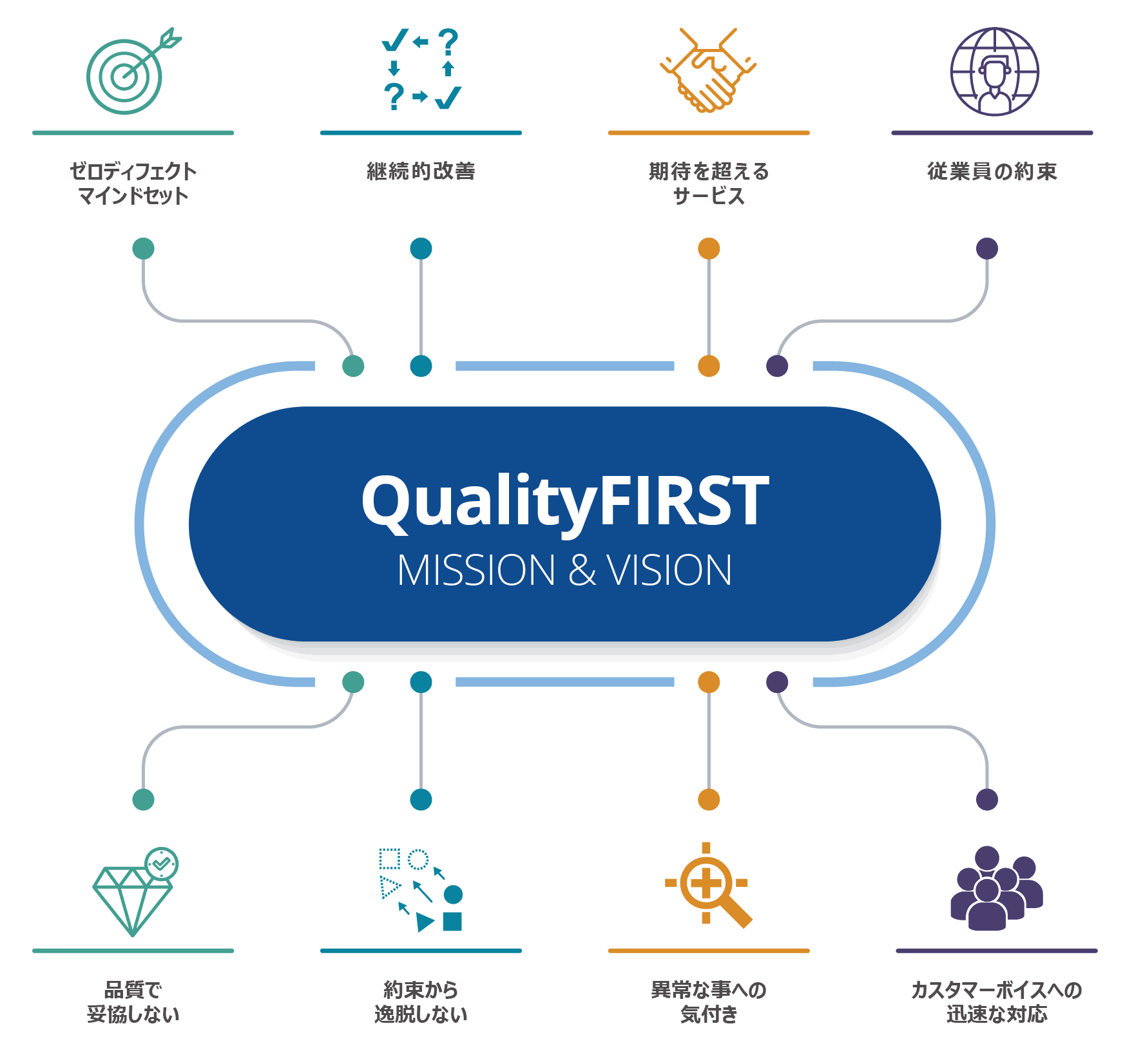

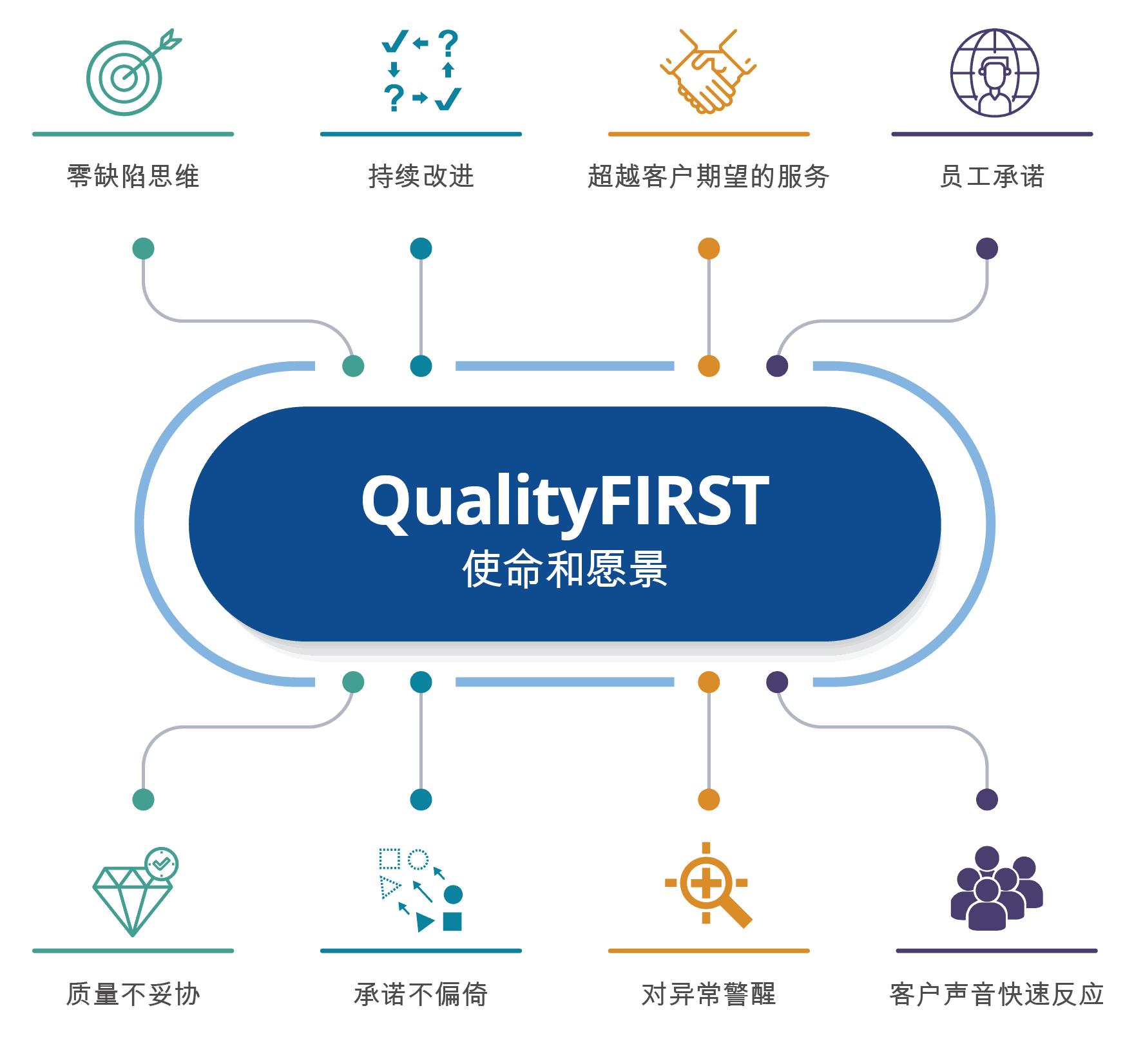

お客様の満足を目指す弊社のコミットメントはQualityFIRSTを通して伝えられます

Amkor はQualithFIRSTの構想を通じて業界をリードする高品質のサービスをお客様にお届けします。

Amkorは、高品質の追求とは製造のみで成し遂げられるものではないと考えています。QualityFIRSTは当社のプロセスに組み込まれ、すべてのAmkor社員に対し同一の高品質基準の姿勢を徹底しています。

Amkor はQualityFIRSTの原則とコンセプトを広く適用し、新製品の開発から製造、管理、販売および顧客サービスに至るまでビジネスのすべての領域でそれを具体化しています。

車載品質

Amkor は最高の品質を備えた世界トップレベルの車載製品OSATです

車載製品に求められる品質要件のため、現在はPPMやPPBではなく、「品質事故の数」が求められます。世界最大の車載製品向けICのOSAT である当社、不良ゼロを通してお客様の要件を上回ることができるように努力を続けています。

車載製品の品質システム

- 不良ゼロのマインドセット

- Amkorの Quality FIRST 文化

- 車載製品のゴールデンルール

- 車載製品の品質認証

- IATF-16949

- AIAGのコアなツールおよび VDA 6.3

- お客様特有の車載製品に関する要件

- 変更管理

- 製品ベースのFMEA/コントロールプラン

車載のプロセス管理

- 車載製品の標準的なプロセスとコントロール

- ファクトリーオートメーション

- ユニットレベルトレーサビリティ(ULT)

- ハンズフリーオペレーション

- 車載専用ライン

- 5S、異物管理

サプライヤークオリティ

弊社の大切なサプライヤーがAmkor のQualityFIRSTを実現する鍵になります 半導体アセンブリおよびテスト産業において

Amkor の世界規模のサプライヤー品質マネジメント(SQM)チームは、サプライヤーがAmkorの品質に対する要件に積極的に取り組んでいただけるように促します。サプライヤーは、各部材がAmkorの要件に適合することを厳しく管理することで、製品とプロセスに対する体系的かつ継続的な改善を行うように奨励されています。

- サプライヤーのシステム要件

- 材料タイプ別の調達(PO)仕様

- 受入れ検査

- 部材タイプ別 IQA 仕様(さまざまな IQA 仕様)

- 部材コントロール - サプライヤー CAR

- 材料 MRB

- サプライヤーの品質システム評価

- 品質システムの監査

- 製造プロセス監査

- 原材料/サプライヤー適合性検査

- サプライヤー監査(社内監査)

- サプライヤーの評価とランキング

工場認証取得

Amkorは、品質管理、環境、衛生と安全管理、情報セキュリティ管理に関する国際的に認められた認証基準を遵守しています。これらの基準に取り組むことで、最高レベルの品質、安全性、セキュリティの確保に努めています。

ご質問やお問合せはこちらまで

以下の「リクエスト」をクリックしてご連絡ください