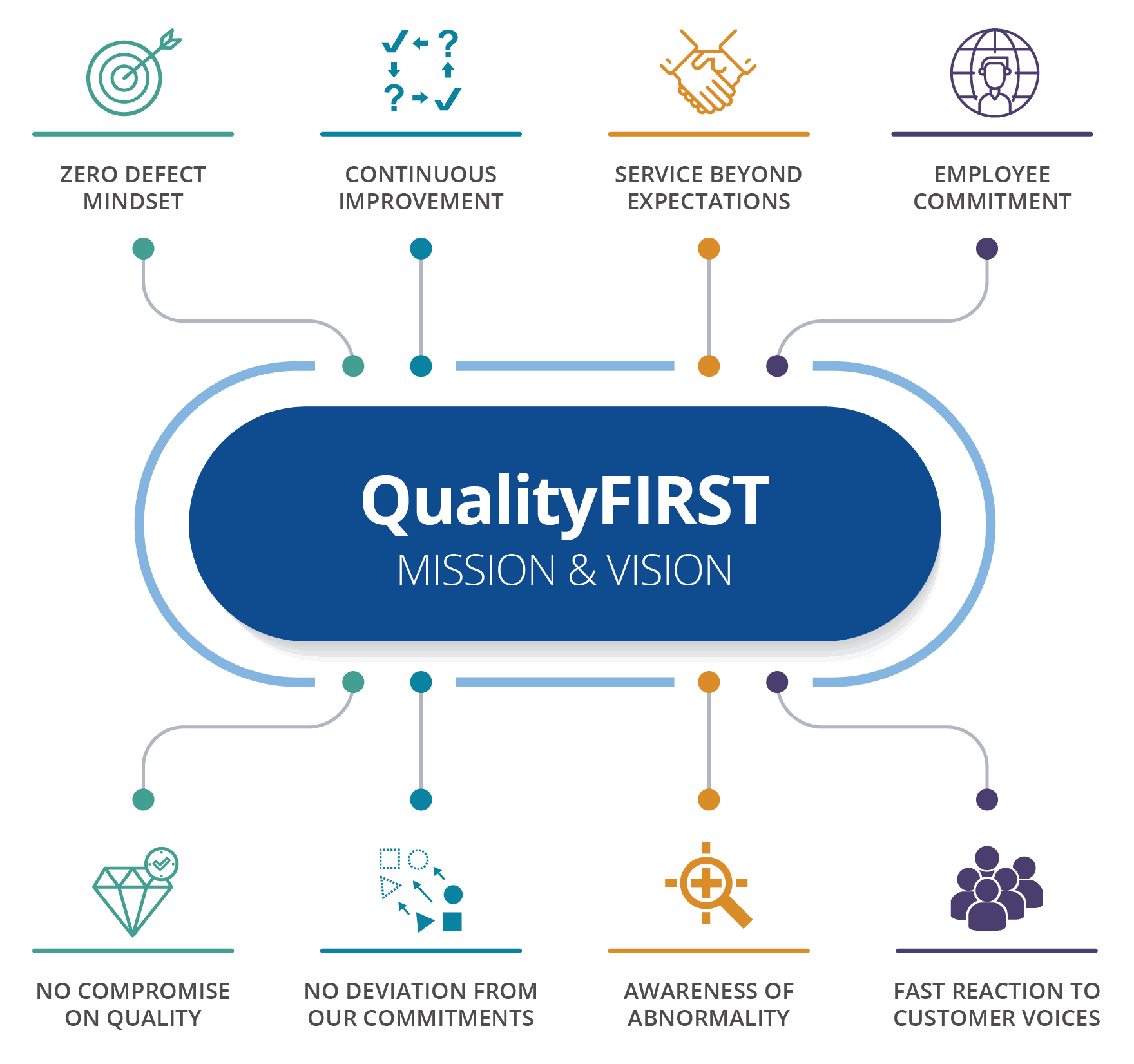

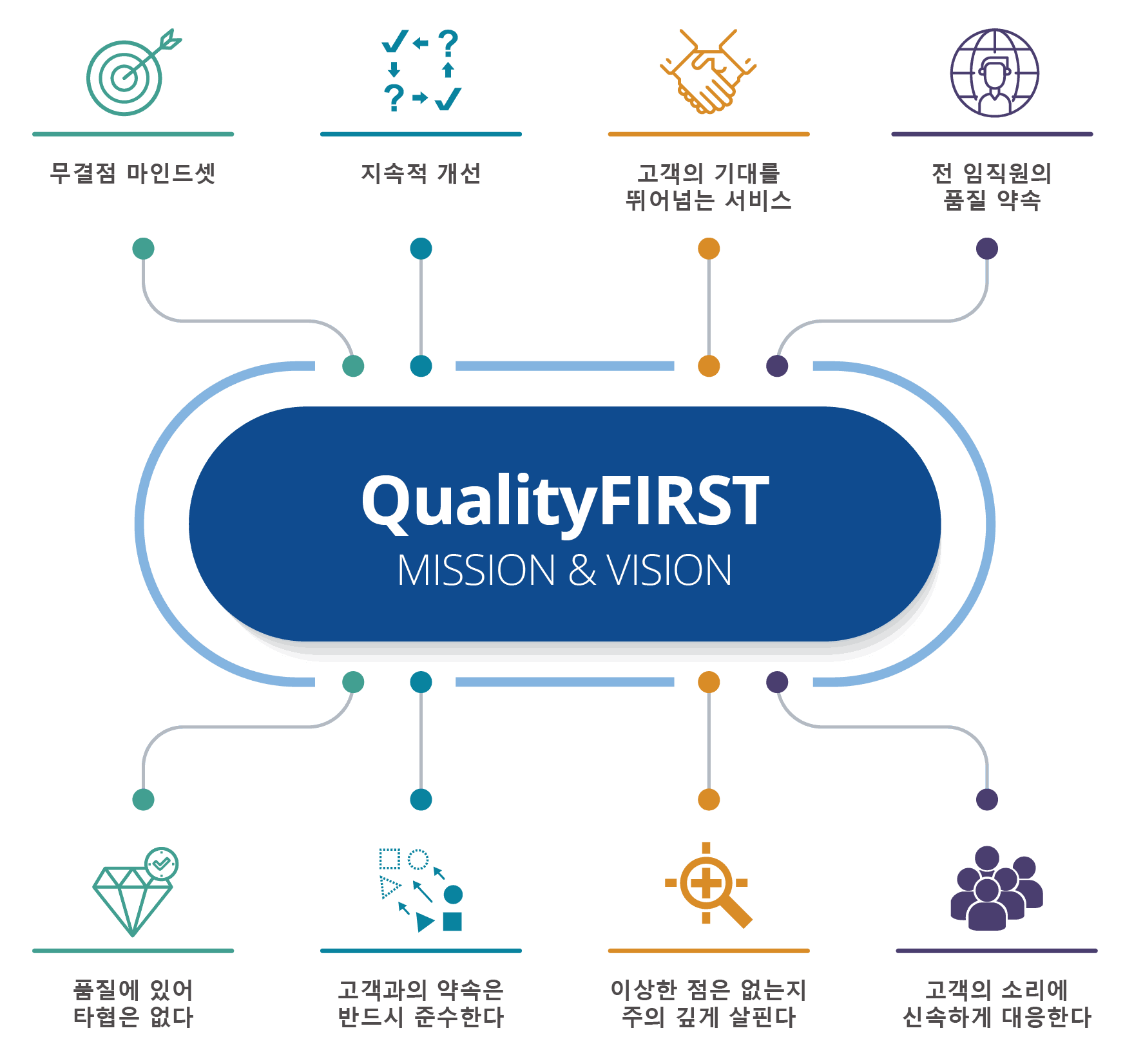

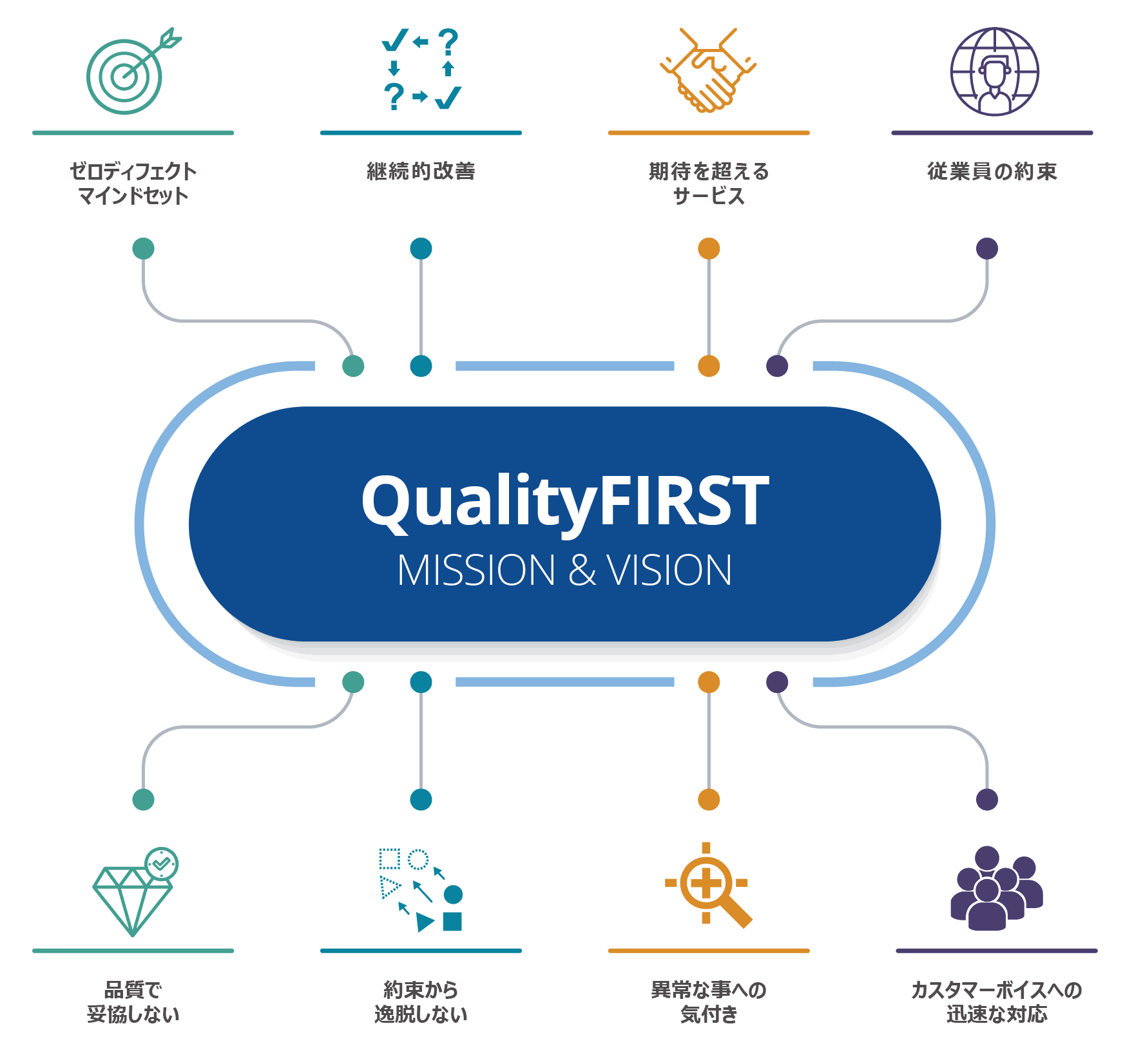

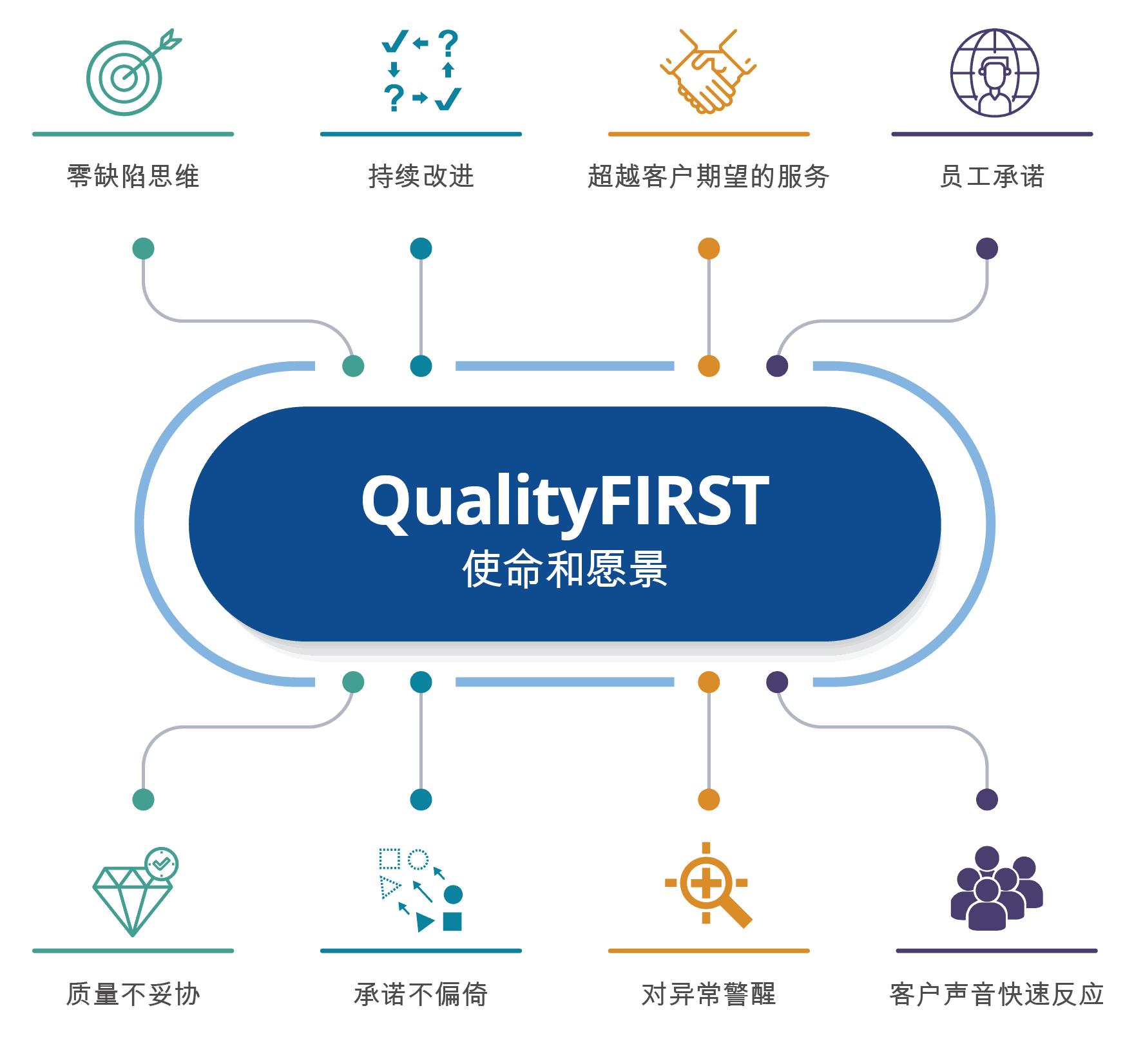

我们通过 QualityFIRST 致力于提高客户满意度

Amkor 通过我们的 QualityFIRST 计划为我们的客户提供行业领先的优质服务。

Amkor 知道,对于质量的追求不应该止步于制造阶段。QualityFIRST 深植于我们的制程,确保 Amkor 的所有员工都秉持相同的质量标准。

Amkor 遵守 QualityFirst 原则和概念,并将其融入到从新产品开发、制造、管理到销售和客户服务等业务的各个领域。

汽车质量

Amkor 是全球顶尖的最优质汽车 OSAT

对汽车质量的期待现在以“质量事故的数量”,而不是百万分之一或十亿分之一来衡量。作为全球最大型的汽车集成电路 OSAT,我们不断努力超越客户要求,力图实现零瑕疵目标。

汽车质量体系

- 零瑕疵思维

- Amkor 的 QualityFirst 文化

- 汽车应用黄金准则

- 汽车质量标准

- IATF-16949

- AIAG 核心工具 & VDA 6.3

- 特定客户的汽车要求

- 变革管理

- 基于产品的 FMEA/控制计划

汽车制程控制

- 汽车标准流程与控制

- 工厂自动化

- 器件级追溯性 (ULT)

- 无手工操作

- 指定资源

- 5S,外来材料控制

供应商质量

我们所重视的供应商是实现 Amkor 在半导体封装和测试行业 QualityFIRST 的关键

Amkor 的全球供应商质量管理 (SQM) 团队推动我们的供应商更主动地满足 Amkor 对于质量的期待。我们鼓励供应商通过严格监控材料的一致性来系统性地持续改善其产品和流程,以便使其符合 Amkor 的要求。

质量要求

- 供应商系统要求

- 不同材料类型的采购 (PO) 规格

异常管理 (MRB/SCAR)

- 进料检查

- 不同材料类型的 IQA 规格(各种 IQA 规格)

- 原材料控制 – 供应商 CAR

- 原材料 MRB

供应商/材料评估与鉴证

- 供应商质量系统评估

- 质量系统审查

- 制程审查

- 原材料/供应商鉴证

- 供应商审查(Amkor 内部)

性能检查

- 供应商评分与定级

工厂认证

Amkor 遵守国际公认的质量管理、环境、健康与安全管理以及信息安全管理认证标准。Amkor 秉持这些标准,确保我们的运营在产品质量、环境人员安全和信息安全方面达到最高水平。

CNS 15506

IATF 16949

ISO 9001

ISO 14001

ISO 15408

ISO 27001

ISO 45001

有问题?

点击下方的 “获取信息“ 按钮,

联系 Amkor 专业人士。