5G RF 제품 테스트 서비스 당면 과제

5G 무선 주파수(RF) 표준 적용이 빠르게 증가하고 있습니다[1]. 지난 4~6 분기 동안 시장에 발표된 보고서와 제품에 대한 관심도가 높아지고 있습니다. 널리 사용되고 있는 RF 애플리케이션에는 휴대폰, WiFi, 자동차, 사물인터넷(IoT), 위치 서비스 등이 있습니다. WiFi와 휴대폰 서비스는 데이터 집약적인 반면, 사물인터넷은 제한된 양의 데이터만을 필요로 합니다.

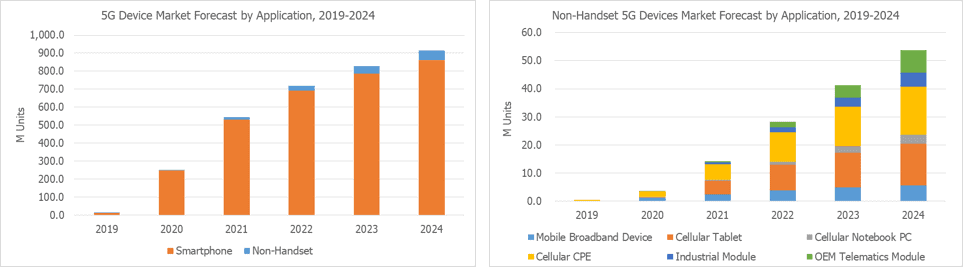

4G 모바일 네트워크 시장 규모 측정 기준에 따르면, 5G 표준 정의가 적용된 그림 1의 수치와 TAM(Total Addressable Market)의 달성 관련 신뢰도가 높은 것으로 나타납니다.

그림 1: 5G 제품의 빠른 성장 전망. 출처: IoT Business News

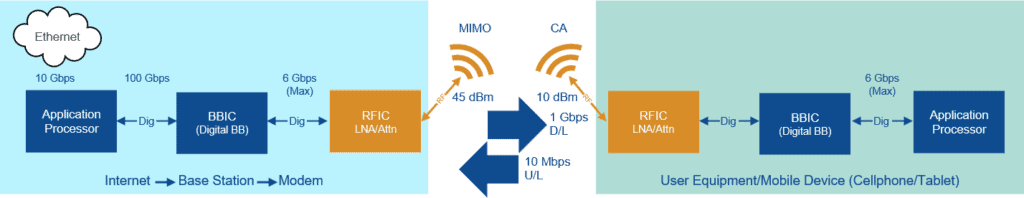

전세계적으로 5G 사양에 맞춰 개발중인 제품들에 대해 이와 유사한 사례들이 많이 있습니다. 5G RF 부품 사용이 많을수록 테스트량이 증가할 것이며, 사용자 장비 도입에 앞서 인프라 개발 및 구축이 선행될 것으로 보입니다. 그림 2와 같이 일반적인 휴대전화 애플리케이션에는 커버리지 영역 내에서 여러 사용자의 휴대전화를 각각 지원하는 휴대전화 타워 기지국이 포함됩니다.

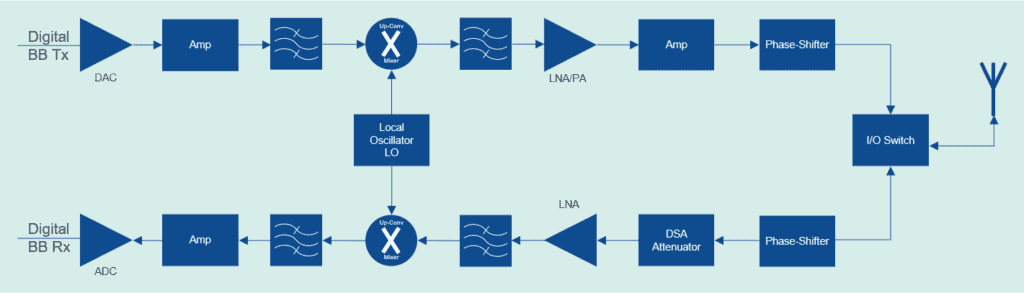

그림 2: 애플리케이션 프로세서(AP), 베이스밴드 집적회로(IC) 및 무선통신용 초고주파 칩(RFIC)을 포함한 양방향 RF 통신 블록 다이어그램

기지국들은 다양한 사용자 장비를 지원할 수 있는 커버리지 영역이 있기 때문에, 사용자 장비에 비해 더 높은 RF Power를 필요로 합니다. 기지국은 플러그인 전원으로 가동되는 반면, 사용자 장비는 휴대 가능하고 배터리로 전원이 공급되기 때문에 전력 효율이 높게 설계되어 있습니다. 일반적인 휴대전화에서 다운로드하는 데이터는 업로드하는 데이터보다 크기가 몇 배 더 크기 때문에, 수신 채널들의 수는 일반적인 전송 채널들의 수보다 더 많습니다. 다중 입력, 다중 출력(MIMO) 및 캐리어 어그리게이션(Carrier Aggregation)[1]과 같은 개념이 프로토콜에 사용되어 유효 대역폭을 증가시킵니다. 수신 채널은 공간 성능 향상을 위해 다중기술[1]을 사용합니다. 이 개념이 본 자료의 핵심 내용은 아니지만, 제품 아키텍처 및 디자인은 테스트 요구사항 및 테스트 방법에 영향을 줍니다. WiFi 기술 기반 애플리케이션은 일반적으로 가정 및 사무실 내에 설치되어 있으며, 최대 RF Power는 제한이 있지만 동적 범위는 제한되지 않습니다. 또한 WiFi 기반 애플리케이션의 대역폭은 보통 휴대전화보다 더 넓습니다.

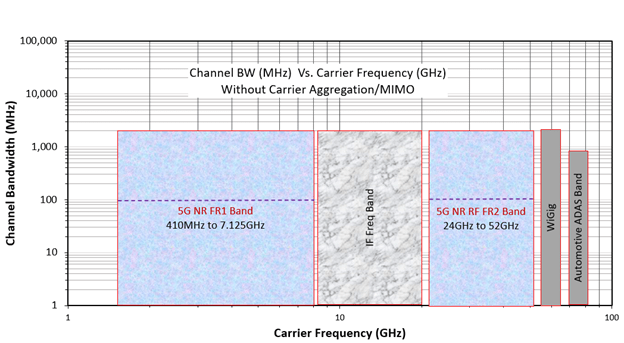

최근 도입된 5G 3GPP 표준[1]은 두 개의 개별 반송 주파수 스펙트럼에서 반송 주파수를 식별합니다. 그림 3과 같이, FR1 반송 주파수는 410 MHz~7.125 GHz 범위, FR2 반송 주파수는 24 GHz~52 GHz 범위에 있습니다. 허용가능한 대역폭은 100 MHz를 초과한 최대 2 GHz 입니다. 서브 캐리어 간격이 좁기 때문에 위상 잡음 및 이득 평탄도(Gain Flatness)에 대한 엄격한 제약이 필요합니다.

그림 3: 3GPP 규격[1]에서 정의된 5G 반송 주파수

5G NR(New Radio) 변조 방식

5G NR 신호 변조 방식에는 CP-OFDM(Cyclic Prefix Orthogonal Frequency Division Multiplexing)과 DFT-S-OFDM(Discrete Fourier Transform Spread Orthogonal Frequency Division Multiplexing)[1] 두 가지가 있습니다.

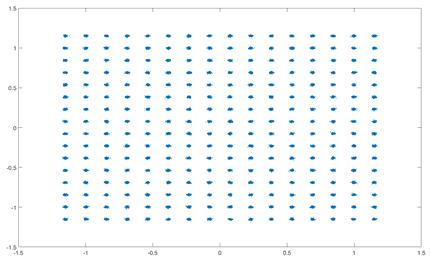

그림 4: Advantest V93K에서 확인된 256-QAM(Quadrature Amplitude Modulation) 5G NR 컨스텔레이션 플롯

CP-OFDM은 다운링크(D/L)용이며, QPSK(Quadrature Phase Shift Keying), 16-QAM, 64-QAM 및 256-QAM이 있습니다. 스펙트럼 효율이 높고 MIMO 및 4G LTE 규격과 호환됩니다. DFT-S-OFDM은 업링크(U/L)용이며, π/2- BPSK(Binary Phase Shift Keying), 16-QAM, 64-QAM 및 256-QAM이 있습니다. CP-OFDM에 비해 구현이 복잡하고 리소스 할당 유연성이 떨어지며, MIMO와 함께 사용되지 않습니다. 5G NR용 서브캐리어 5개의 간격은 15 kHz~240 kHz입니다. 그림 4는 256-QAM을 보여줍니다.

5G RF 제품 & RFIO

최신 다이렉트 및 헤테로다인 변환기 아키텍처[2]에는 디지털 베이스밴드 I/O가 있습니다. 디지털 베이스밴드는 아날로그 인페이즈 및 쿼드러쳐 (In-Phase/Quadrature) 파형을 생성하는 DAC(Digital-to-Analog Converter)에 데이터를 공급합니다. 이러한 파형은 국부 발진기(LO) 신호와 혼합되면, 데이터를 상향 변환하여 수신기(Rx)로 전송되는 변조된 중간 주파수(IF) 또는 RF 신호를 생성합니다. 신호 전송은 동축 차폐 케이블 또는 무선으로 이루어집니다. 전송 전, 특히 무선일 때 신호 증폭이 필요할 수 있습니다. 또한, 수신기는 하향 변환을 위한 신호를 공급하기 전에 수신된 신호를 증폭해야 할 수도 있습니다. 하향 변환된 신호가 ADC(Analog-to-Digital Converter)에 들어오면, 애플리케이션 프로세서 처리를 통해 디지털 배이스밴드로 변환됩니다. 그림 5는 이러한 단계를 보여 줍니다.

그림 5: 단순화된 송신기(Tx) 및 Rx RF 체인 블록

IDM 고객사는 다양한 RF 제품의 어셈블리 및 테스트 서비스를 의뢰합니다. 트랜스시버, 저소음 증폭기(LNA), 전력 증폭기(PA), 디지털 스텝 감쇠기(DSA), 필터 및 혼합기 등 다양한 제품들이 있습니다 타겟 애플리케이션에 따라, RF 입출력 채널의 수는 상이할 수 있습니다. 대역폭, 위상 잡음, 상호 변조 왜곡(IMD), 위상 및 진폭 해상도/정밀도 및 기타 테스트 요구사항도 다를 수 있습니다.

생산 테스트용 DUT(Device Under Test)의 송신기 특성 사양에는 송신 전력 및 RF 스펙트럼 방출(점유 대역폭, 대역 외 방출, 인접 채널 누출 비율(ACLR) 및 IMD)이 포함됩니다. 생산 테스트용 DUT 수신기 특정 사양에는 수신 감도, 최대 입력 레벨, 인접 채널 선택도, 차단, 스퓨리어스 응답 및 IMD가 포함됩니다[1].

5G RF 하위 시스템을 이용한 자동 테스트 장비(ATE) 테스터 및 툴링(Tooling)

Advantest, Teradyne, National Instruments 및 Cohu는 최근 자사의 기존 ATE 제품 업그레이드 계획을 발표했습니다. 앰코는 제조 사업장에서 고객 제품을 테스트하기 위해 ATE의 RF 하위 시스템 하드웨어 및 소프트웨어 계측 인프라를 활용합니다.

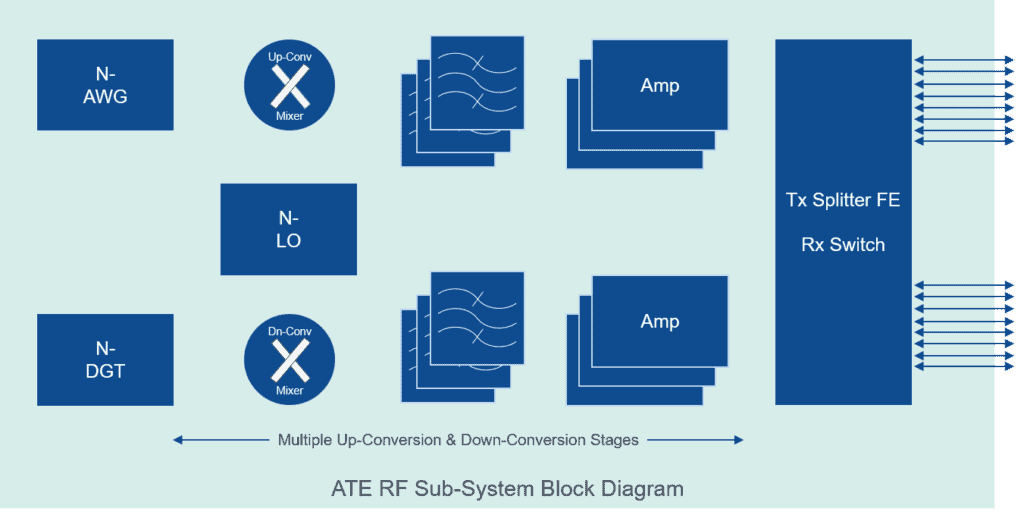

ATE 공급업체는 일반적으로 고객 테스트 애플리케이션 개발을 위해 기기 리소스의 범용 슈퍼셋(Superset) 구성을 설계합니다. 임의 파형 발생기(AWG), 디지타이저(DGT), LO, 필터, 증폭기, 톤 컴바이너, 전송 신호 스플리터, 수신 신호 스위치 및 광대역폭, 동적 작동 범위는 각 고객의 모든 새로운 5G RF 애플리케이션에 대해 고려해야 하는 트레이드오프(Tade-Off)를 제공합니다. 애플리케이션별 주파수의 위상 잡음 및 계측기 설계의 진폭은 EVM(Error Vector Magnitude) 테스트에 직접적인 영향을 미칩니다 100 kHz 및 -10 dB 이상의 오프셋에서 -110 dBc/Hz의 위상 잡음은 5G 지속파(CW) 주파수 범위에서 (일반적으로) 허용 가능합니다. 일반적인 광대역 고객 제품 애플리케이션에서는 주파수 및 진폭 전환이 필요합니다. 전환 시간은 전체 테스트 목록 실행 시간에 영향을 줍니다. 전환 시간이 가장 짧은 테스터는 생산 테스트에서 가장 효율적입니다. 그림 6은 ATE 블록 다이어그램을 보여줍니다.

그림 6: 단순화된 ATE 블록 다이어그램

맞춤형 툴링(프로브 카드 및/또는 로드 보드)은 테스터 리소스를 장치, 핀 또는 범프에 연결할 수 있도록 개발되어야 합니다. 프로브 카드 공급업체는 웨이퍼 프로브 서비스를 위해 프로브 핀 기술을 제공합니다. 50 GHz를 초과하는 5G RF 반송 주파수는 임피던스 정합(Impedance Matching), 핀 및 사이트 간 신호 분리가 과제입니다. 패키지된 부품의 경우, 로드 보드, 소켓 및 소켓 핀 기술 공급업체가 핀 기술을 제공합니다. 5G RF 반송 주파수와 프로브 핀의 과제는 유사합니다. 이러한 주파수에서 허용되는 삽입손실(S-Parameter S21)은 일반적으로 -10dB 이하이며, 주파수 범위의 반사손실(S11)은 일반적으로 -10 dB 보다 좋습니다. 일반적인 애플리케이션에 허용되는 핀 간 절연 수준은 주파수 범위 -45 dB 보다 우수합니다.

RF 성능 및 정확도 사양은 공급업체가 테스트 헤드 신호 전달 인터페이스에 대해 보장합니다. 테스터 공급업체는 문서화된 사양 내에서 성능을 교정, 검증 및 진단할 수 있도록 교정 시스템(하드웨어 및 소프트웨어)을 개발하고 제공합니다. RF 기기의 정확도 사양은 온도 변화에 민감합니다. 대부분의 경우 ±5°C (또는 더 엄격한) 온도 변화는 기기의 자가 보정 루틴을 시작하게 합니다. 전력, 신호(디지털, 아날로그/RF) 및 클럭을 사용하려면 교정 평면(Calibration Plane)을 테스트 헤드에서 디바이스 핀으로 이동해야 합니다. 이 경로에는 프로브 카드 또는 로드 보드의 트레이스가 포함됩니다. 당사는 디 임베딩(De-Embedding) 기술 적용 및 루프백(Loopback) 또는 맞춤형으로 개발된 SOLT(Short, Open, Load, Through) 구조를 사용하여 필요한 RF 신호 정확도를 테스트 대상 기기에 전달을 돕는 고유한 이점을 제공합니다. 일반적으로 교정을 위한 맞춤형 표준 개발에는 추가 작업이 필요하지만, 인하우스 패키지 설계에서는 가능합니다. 대부분의 경우 골든 루프백 DUT 기술로 원하는 정확도를 충분히 달성할 수 있습니다.

어셈블리 및 테스트 결합

당사의 어셈블리 및 테스트 부서는 5G RF 엔지니어링 개발에 이어 생산 테스트가 가능하도록 긴밀히 협력하고 있습니다. 이 덕분에 같은 사업장에서 어셈블리 및 테스트 턴키 솔루션 제공이 가능합니다. 앰코는 2018년 7월 5G용 AiP/AoP SiP 패키지 첫 생산 후 2019년 보도자료를 통해 이를 공식 발표습니다[3].

최근 어셈블리 및 패키징 기술이 발전함에 따라 5G 트랜스시버 및 RF프론트엔드(RFFE)장치와 같은 RFIC에는 패키지 내에 안테나를 내장할 수 있습니다. 마찬가지로 SiP(System in Package) 장치에는 프로세서, 메모리, RFIC 주변 장치, 전력 증폭기, 저소음 증폭기, 위상 배열 및 안테나 구조와 같은 관련 컴포넌트를 IC 패키지 내에 통합했습니다. 안테나는 프런트엔드의 중요한 구성 요소이며 특정 주파수 대역에 맞게 조정해야 합니다. 오늘날 설계되고 있는 5G NR FR2 호환 고객 제품은 3GPP 규격에 정의된 대로 특정 운영 대역에서 성능이 조정됩니다[1]. 데이터 집약적인 애플리케이션은 패키지 내 다수의 무선 패킹 보증을 위해 작동 주파수 대역별로 튜닝된 여러 개의 안테나가 필요합니다.

이전 및 현재 RF 기기는 전도성 테스트를 합니다. DUT에서 들어오고 나가는 RF I/O는 케이블을 통한 임피던스 제어 경로와 테스터 RF 기기로의 차폐된 PCB 마이크로 트레이스로 전기적 연결이 가능합니다. 앞서 언급한 바와 같이, 모든 ATE 공급업체가 개발하는 5G RF 테스트 솔루션에는 전도성 RF 동축 인터커넥트가 포함됩니다. 안테나 내장 패키지의 대량 생산 테스트 실현을 위해, 신호 손실은 최소화하면서 RF 에너지 송수신이 가능한 상호 연결 테스팅이 필요합니다. 안테나 전송 이론[7]은 송신기와 수신기 사이에 최소한의 공간적 분리를 요구하며, 이 분리는 반송 주파수에 따라 다릅니다. RF I/O 채널 수와 다중 사이트 테스트 요구사항은 생산 테스트의 복잡성을 가중시킵니다. 현재 검토 중인 테스트 옵션에는 패치 및 혼 안테나, 빔 포밍(Beam Forming) IC, 내장형 방향 커플러와 도파관이 포함됩니다. 이러한 솔루션들은 대량 생산에 적합하지 않고 안테나 수 증가에 따라 확장이 가능하지도 않습니다. 이는 주로 테스터 인터페이스에서 핸들러의 물리적 공간 요구사항 때문입니다

IDM은 테스트 장비 요구사항을 단순화하고 경제적으로 만들기 위해 트랜스시버의 루프백 DfX(Design for Excellence) 모드를 허용하는 설계구조를 디자인해 왔습니다. 패키지에 내장된 안테나는 소형화와 전반적인 통합을 가능하게 하지만, 반송 주파수의 새로운 5G NR 운영 대역용 애플리케이션의 최종 성능 조정 유연성을 약하게 합니다. 당사는 생산 테스팅을 위한 OTA(Over-The-Air) 테스트 도전과제를 해결하기 위해 공급업체 및 고객과 지속적으로 협력하고 있습니다.

부가가치 제안

상위 레벨에는 두가지 주요 생산 테스트 운영 모델이 있습니다. 첫번째 테스트 운영 모델은 고객이 테스트 컨텐츠와 5G RF 테스트 장비를 선정하여 앰코가 생산에 사용하도록 하는 것입니다. 두 번째 모델은 생산 테스트를 가능하게 하는 고객 요청 엔지니어링 서비스를 제공합니다. 이 경우, 당사 테스트 개발 팀은 고객과 긴밀히 협력하고 각 고객의 테스트 개발 엔지니어링(TDE) 요구 사항에 맞는 맞춤형 요구사항을 충족합니다. 부가가치 TDE 서비스의 예는 다음과 같으며, 이에 국한되지 않습니다.

- 매칭되는 5G 지원 테스터 선택

- 매칭되는 프로버 및 핸들러 선택

- 다중 사이트 생산 테스트를 위해 테스터의 적절한 할당을 매칭하는 5G 테스트 툴(프로브 카드, 로드 보드) 설계

- 고객의 테스트 사양에 따라 생산 테스트 프로그램, 테스트 패턴 및 테스트 파형 개발과 디버깅

- 제품 검증

- 제품 특성 테스트 루틴

- 수율 최적화, 저수율 불량 분석 및 제품 설계 피드백 (예: 불량 분석 시 제조 및 어셈블리 패키징 결함의 근본 원인 파악을 위해 X-Ray 또는 층 분리가 필요할 수 있습니다.)

- 완제품을 효율적으로 처리할 수 있는 맞춤형 백엔드 플로우

RF 테스트 개발 엔지니어링 그룹은 이전 및 현재의 RF 기술용 테스트 솔루션 및 테스트 콘텐츠 개발 경험이 풍부하며, 해당 자료에서 논의된 5G 테스트 과제를 해결하기 위한 전문 지식을 지속적으로 구축하고 있습니다. 이 그룹은 FR1 및 FR2 RF 스펙트럼 겸용 모바일 5G RF 제품 및 기지국용 테스트 솔루션을 활발히 개발 및 제안하고 있습니다 이러한 테스트 솔루션은 위에서 설명한 3GPP 표준 호환 ATE 하드웨어 및 소프트웨어 테스트 툴을 이용합니다.

내부 생산 테스트 프로세스는 수년에 걸쳐 발전해 왔으며 DFM(Design For Manufacturing) 규칙을 5G RF 생산 테스트에 구현할 수 있게 합니다. 5G RF 생산 테스트 결과를 수집, 분석 및 유지하는 것은 테스트 방법, 흐름 및 컨텐츠를 점진적으로 개선하는 데 필수적입니다. 특정한 경우, 테스트 엔지니어는 IC 설계 및 제조 공정 엔지니어에게 중요한 피드백을 제공합니다. 테스트 장비 전반에 걸친 다중 사이트의 5G RF 테스트 결과가 정리된 SBL(Statistical Bin Limit)은 시스템 장비 관련 불량을 식별하고 이러한 요인을 제거하는 데 도움이 될 수 있습니다. 또한 이것은 최적의 테스트 장비 활용을 보장하고 전체 생산 처리량을 개선합니다.

많은 고객들이 TTM(Time To Market) 목표 기반의 제품을 보유하고 있으며 지적 재산권(IP) 침해 및 보안에 민감합니다. 이러한 모든 고객 문제 처리를 위해 발달된 시스템과 프로세스가 마련되어 있습니다.

앰코 생산 테스트는 향후 몇 년간 예상되는 다양한 5G 제품을 테스트할 수 있도록 준비해 왔습니다. 여기에는 사용자 기기 (모바일 디바이스) 발전에 선행 될 것으로 예상되는 5G 기지국 및 인프라 장비가 포함됩니다.

요약

5G RF 생산 테스트 비즈니스는 규모가 크고 빠르게 성장하고 있습니다. 앰코의 생산 테스트 팀은 전체적인 5G RF 생산 테스트 서비스가 모든 테스트 역량 및 도전 과제를 충족하고 극복할 수 있도록 어셈블리 패키징 담당자, ATE 공급업체 및 고객들과 긴밀히 협력합니다.

참고 자료

- 3GPP TS 38.101-1 V16.1.0 (2019년 9월)

- 광대역 RF 아키텍쳐 옵션 – Peter Delos, Analog Devices

- 앰코 디바이스 패키지

- Antenna In Package/Antenna On Package

- 앰코 Antenna in Package – 기사

- 앰코 패키지 – 2019년 보도 자료

- Fresnel Far Field Region 또는 Antenna Theory

작성자 정보

Vineet Pancholi, 테스트 기술팀 수석, Amkor Technology, Inc. in Tempe, AZ

Vineet은 2019년 1월 앰코에 입사해 현재 5G RF와 고속 디지털 생산 테스트 방법론 기술 개발을 주도하고 있습니다. 앰코 입사 전 Vineet은 Microchip Technology의 테스트 개발팀에서 근무했습니다. 그전에는 19년 동안 Intel에서 테스터 공급업체 관리, 테스트 기술 개발 (번인, 최종 및 시스템 수준 테스트) 및 RF 테스터 설계 등을 포함한 다양한 테스트를 담당했습니다. Vineet은 반도체 기기 테스터 특허를 보유하고 있으며, 애리조나 주립 대학에서 물리학 및 전기공학 석사를 취득했습니다.