Ultra-Compact, High-Performance Packaging for Power and RF Applications

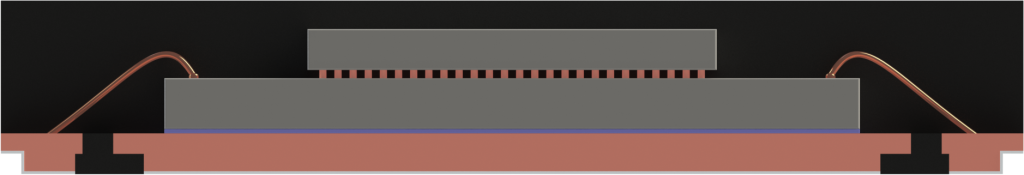

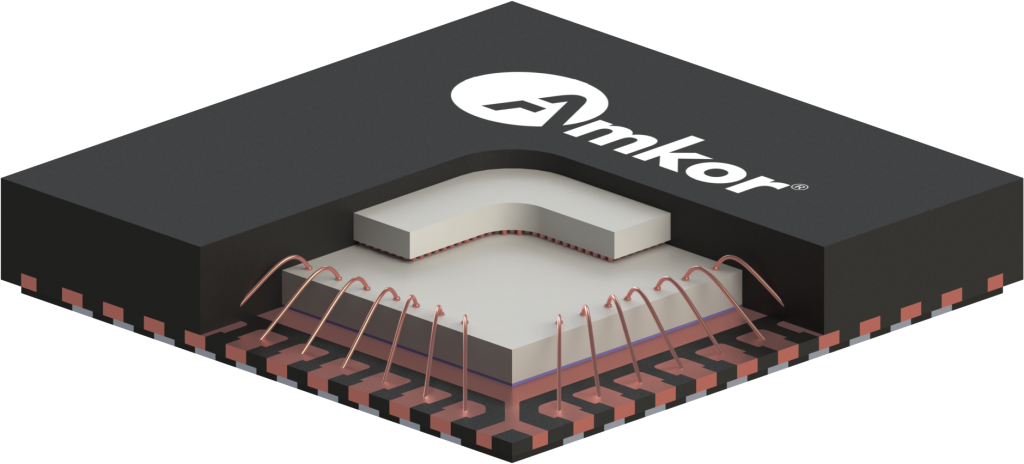

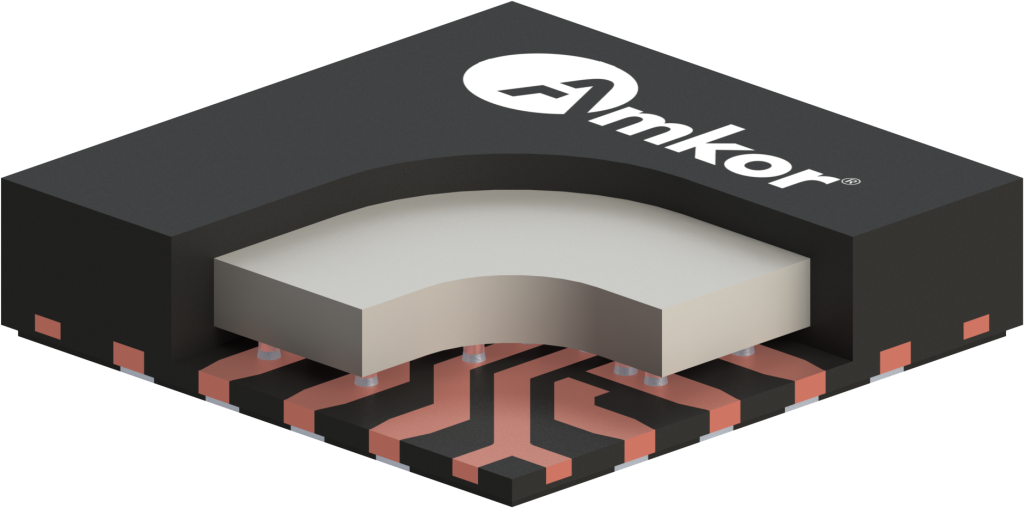

Amkor’s Flip Chip MicroLeadFrame® (fcMLF®/fcQFN/SON/DFN) package delivers cutting-edge performance in a compact, cost-effective form factor. Designed with a copper leadframe substrate and advanced interconnect technology, this near-CSP plastic-encapsulated solution supports all of Amkor’s bumping options, including copper pillar and Pb-free solder. The result? Up to 70% smaller package size compared to traditional wire-bonded MicroLeadFrame packages of the same die size—enabling sleeker designs and higher functionality.

Engineered for reliability and efficiency, the fcMLF package features perimeter lands for robust electrical connections to the Printed Wiring Board (PWB). It also incorporates Amkor’s ExposedPad technology, delivering superior thermal and electrical performance. By exposing the die attach paddle on the bottom surface, heat is efficiently dissipated when soldered directly to the PWB—ensuring optimal power handling and long-term device reliability.

Smaller. Smarter. Cooler. Amkor’s flip-chip MicroLeadFrame is the ideal solution for next-generation applications that demand high performance with a minimal footprint.

애플리케이션

Amkor’s fcMLF package delivers unmatched versatility and reliability for today’s high-performance applications. Ideal for power management ICs (PMICs), DC/DC converters, and RF switches, fcMLF combines advanced design with proven manufacturing excellence to meet the demands of compact, energy-efficient systems.

To ensure compliance and ease of assembly, fcMLF supports wettable flank designs—including dimple and step-cut configurations—enabling fast, accurate visual inspection without X-ray after board mounting. This feature is critical for automotive-grade devices, where quality assurance and reliability are non-negotiable.

With its space-saving footprint, robust thermal performance, and automotive-ready inspection capability, fcMLF is the smart choice for engineers seeking innovation without compromise.

Amkor’s fcMLF technology delivers advanced performance through several key innovations. Copper pillar bumping enables a fine 160 μm bump pitch for leadframe designs, supporting higher-density interconnects. Molded underfill (MUF) eliminates the need for costly traditional underfill processes, while flux dipping of the die removes the requirement for pre-tinning the leadframe, streamlining assembly. The Saw MLF® process flow ensures precision and reliability.

This package offers superior thermal management and high-frequency signal performance, proven to operate at ≥20 GHz and capable of handling more than 4 W—making it an ideal solution for power management IC (PMIC) applications.

Highlights:

- Package size reduction by 70%

- I/O count range is: 1-76

- Die size: 0.5 x 0.5 mm to 9 x 9 mm

- Package size: 1 x 1 mm to 10 x 10 mm

- Package thickness: 0.35 mm to a maximum height of 1.45 mm

- Bump type:

- Cu Pillar

- Pb-free Solder

- Bump pitch:

- Inner lead pitch: Minimum 160 μm

- Bump gap (same net): 50 μm

- Turn-key solutions – Design, bumping, wafer probe, assembly and final test

The package is designed to meet stringent automotive industry requirements, including:

- Fine lead pitch configurations of 0.50 mm and 0.65 mm

- Increased solder-fill height along the lead side area to enhance joint integrity

- Ball lift resistance (BLR) performance equal to or exceeding that of conventional designs

- Elimination of post-SMD X-ray inspection requirements

This process has been qualified and released to high-volume manufacturing (HVM) by Amkor.

|

|

Amkor devices are assembled using optimized package designs and qualified, high-reliability semiconductor materials to ensure robust performance and long-term reliability. All packages are fully compliant with JEDEC standards and are capable of meeting AEC-Q100 requirements for both Grade 1 and Grade 0, supporting operation in demanding automotive environments.

- Moisture sensitivity characterization: JEDEC level 1*, 85°C/85% RH, 168 hrs

- uHAST: 130°C/85% RH, 96 hrs

- Temp cycle: -65°C/+150°C, 500 cycles

- High temp storage: 150°C, 1000 hours

*Depending on the bill of materials (BOM), body size and design

|

|

|

|

Q & A

앰코에 대해 궁금한 점이 있다면

하단의 ‘문의하기’를 클릭하세요.